Resin Shed vs. Wood Shed: Amazing Review For Your Need.

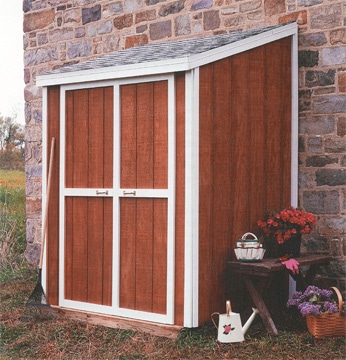

When it comes to choosing the perfect storage solution for your backyard, the decision often boils down to two popular options: resin shed or a wood shed. Each type of shed offers distinct advantages and comes with its own set of drawbacks. Resin sheds are celebrated for their durability, low maintenance, and ease of assembly, […]

Resin Shed vs. Wood Shed: Amazing Review For Your Need. Read More »