Learn how to build shed trusses correctly. Shed trusses can be an intimidating thing to build. Especially if you do not remember your math equations from school Geometry. There are many types of sheds. So there are many types of shed trusses you may need to build. We explore how to build the basic gable shed trusses.

Types Of Shed Trusses

Most people building a shed will start with a good set of shed plans. If you do not have a good plan, then check out shed plans here. Once you find the shed design and shed plans, then you are ready to build.

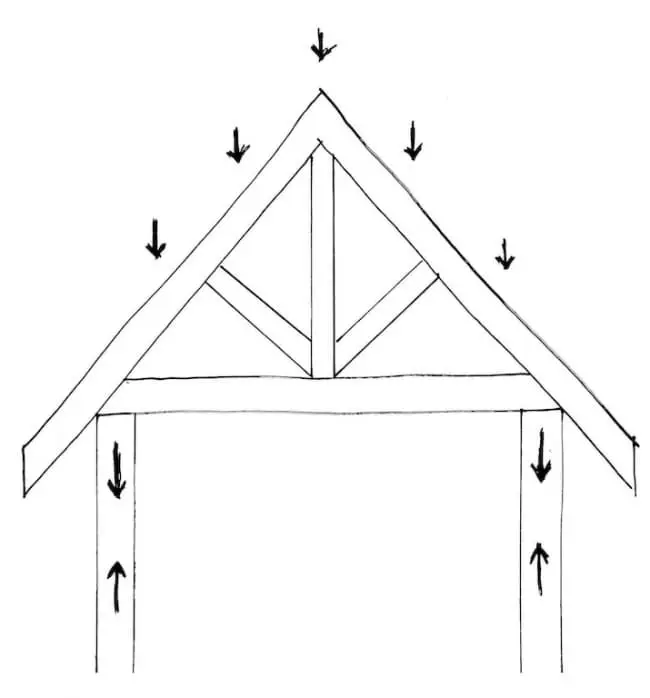

You will begin with landscaping and preparing the ground for the build. Once the foundation is done you will build the perimeter of the shed over the foundation. Then, you will build the floor. Once this is accomplished you will start with the roofing trusses. The shed floor is needed to build the shed trusses. Because the trusses will need to be built with the floor dimensions.

There are many types of shed trusses because there are many types of shed designs. Below is an example of some of the most common sheds.

A lean to shed has a roof that is angled from back to front. This will allow the water to drain in one direction. This roof truss is only one angle and a board that goes from high to low and back to front.

In addition to the lean to shed there is a gable shed roof. This roof is more complex because of the two different angles with the roof. The gable shed has a roof like a house so the roof trusses will have a peak in the middle. The truss sides will be equal in length and width to fit equally on the shed walls.

Finally there is a barn type or gambrel shed roof. This is similar to the Gable shed because the trusses will be in two different cuts because of the two different angles. You can see this in the picture below.

Materials Needed

There are many materials needed to build the shed roof trusses. However, you will have most of the materials purchased already according to your shed plans. Having said that you should already have your shed foundation and floor done at this time. Because you will fabricate your shed trusses on the shed floor.

If you have trouble with your roof angle and pitch calculations. Then, look at this rafter calculator here by Blocklayer.com

The most important think you need is 2×4’s.

In regards to tools you will need a speed square. There is a great one by Swanson that you can find more about here.

It is also recommended to have a proper impact drill. I always like the ones by Dewalt. If you are unsure about which one is good for you then you can read about them here.

The proper framing nails and construction framing screws. These should be 3 inches long and galvanized. If you are unsure as to which ones you will want or need then check out the breakdown of screws here.

Also, you should use nail glue for added stability. I have always recommended liquid nail and you can find which one is right for your job here.

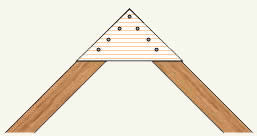

Furthermore, you may need a truss connector plate. This is a plate that connects the trusses together. The plate is made of light gauge galvanized metal with teeth. Therefore, the teeth can connect into the wood of the truss frame. Find the best one for you job and at the right size here. Furthermore, you can use OSB board or plywood to make a wood gusset to hold the frame together instead of the connector plate. This is outlined below.

Build Shed Trusses Correctly - Gable Shed Without A Birdsmouth.

Shed Truss Parts

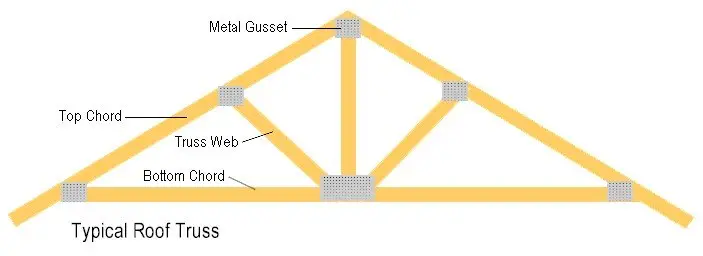

There are three parts to the roof truss that you have to know. The bottom chord, which is the bottom of the framed truss. Then there is the top chord or rafters that are angled to make the roof pitch. Finally there are the gussets that hold the framed truss together. See gusset construction below.

To begin with make sure your 2×4’s are inspected for warping, etc… There may be crowning on the 2×4 (as noted in the picture below) and make sure you mark that so you know to build the truss with the crown upward. Go through and mark your 2×4’s as needed.

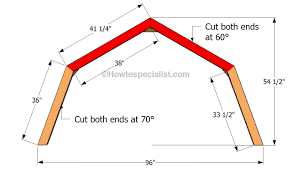

You will need to evaluate your plans and make sure you have the right pitch and angles for your roof. Hence, I will use a basic 30 degree roof pitch in our example.

When starting this process you will use the floor of your shed for the construction. Thus, you will build a framing jig on the floor so you can rapidly make one roof truss after another.

Start With The Bottom Chord

Start with the bottom chord. Measure the width of the floor and add about an extra quarter inch. Then cut that 2×4 for the bottom chord at that length.

Next you will make a 60 degree angular cut at each end of the bottom chord. Use your speed square for the measurements. The rafter or top chord will attach to the bottom chord at that angle. See the picture below.

Make sure you marked the crowns of the bottom chord and cut the bottom chord with the crown facing up.

Build The Top Chord or Rafter Peak

Once that is finished we have to cut the rafters. If the bottom chord angle is 60 degrees, then the angle where the rafters meet is going to be 30 degrees. So use your speed square and measure your angle. Then cut the rafter angle at 30 degrees for two 2×4’s. This will allow them to join and form the peak of the roof and let the other end fit nicely at the 60 degree angle of the bottom chord.

Now you have extra 2×4 hanging over the bottom chord. So, consult your plans and find out what will be done with your fascia and soffit. The amount of overhang will be determined by those factors.

Gusset Construction or Truss Connector Plates

Moving right along we have the bottom chord cut to the right length and angles on the end. We have both rafters cut with the proper peak angle and they fit nicely at the edge of the bottom chord. In addition, you have the length of the rafters cut to the specifications of your shed plans to accommodate the fascia and soffits.

The gussets are not that hard to make but you have to get the right strength of ply wood or OSB board. If these boards are not very sturdy then neither will be your framed truss.

Position the bottom chord and rafters along the floor will they will be located. Once they are connected at the right place then place your plywood piece over the two boards and trace out an outline for the gusset to hang over and attach the boards together as in the diagram above.

Now, go through and cut the proper amount of gussets for the amount of trusses you will need. In our example it will be three gussets for each truss.

Shed Jig For Faster Truss Construction

Don’t get lost yet. It is time to assemble the first truss and build the framing jig at the same time. Mark the middle of the shed floor with a chalk line. This will allow you to place the peak of the roof at the right spot in the middle of the floor.

Now install a brace at the end of the floor so the bottom chord can rest on the floor width wise and you can center the chord across the width of the floor. The brace will hold it in place. Now place the two rafters with their peak at the middle of the chalk line and the ends resting along the bottom chord. The entire truss should be laying flat on the shed floor exactly as it will fit for the roof but it will be lying on the floor.

Once everything is in place get some scrap pieces of 2×4 and place each one along the framed truss to make an outline. Once in the proper place, screw them into the floor making a frame or jig. This will allow you to just place the next pieces of wood in the exact same place as the first allowing the assembly of the next truss to be easier. See the picture below.

Final Shed Truss Assembly

Place wood glue at the end of the board where they will meet. Further, make sure you place wood glue on each of the three gussets. Place a gusset on each corner and screw or nail it into place. Once all three gussets are attached and glued down the truss is finished.

Just use your jig that you built on the floor to put the pieces of the next truss together. All you have to do is build all the trusses the same way. Once you build all the trusses just remove the scrap wood parts that make up the truss jig. Now you can move on to the next phase of construction. You can check out my post here on steps for shed construction.

Shed Trusses Built Without A Birds Mouth

The Birdsmouth Cut Out Truss

This is a special circumstance because some shed plans will have the top chord attach to the roof with a birdsmouth cut out. As in the example above the bottom chord ran the width of the shed. Then the end of the bottom chord was cut to allow the top chord to overhang.

However, there is another way of constructing the truss. The alternative is to have the top chord attach directly to the wall via a cut out. This cut out is called a birdsmouth cut out.

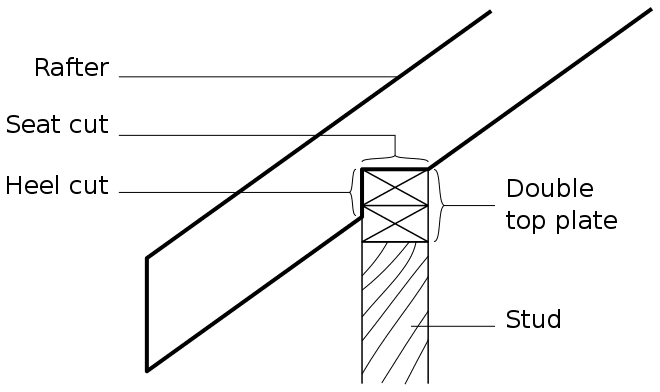

A birdsmouth is an indentation cut into the rafter. The cut has a seat cut, which rests on the top plate. There is also a heel cut that rests along the wall. Look at the picture below. There will be no bottom chord in this type of shed truss build.

Check out the video below demonstrating this type of truss build.

Videos

Shed Trusses Built With A BirdsMouth

Conclusion

Now you know how to build shed trusses correctly. It isn’t that hard if you have the right set of shed plans. You can find those here. Get the proper tools and materials required for the job. Plan out your process and build the shed foundation and floor.

Build your first truss with or without the birdsmouth cut. You will make the truss jig so you can easily assemble the rest of the trusses quickly. Once the trusses are built, then put them aside for installation after the walls are built.

All the best and I hope this helps.

JB